2113209513, 2113209613

PERFECTRAIL®

| Availability: | |

|---|---|

| Quantity: | |

1. Easy to Install

Fully-assembled unit includes everything you need for strut replacement. No need for coil spring compressor and special tools.

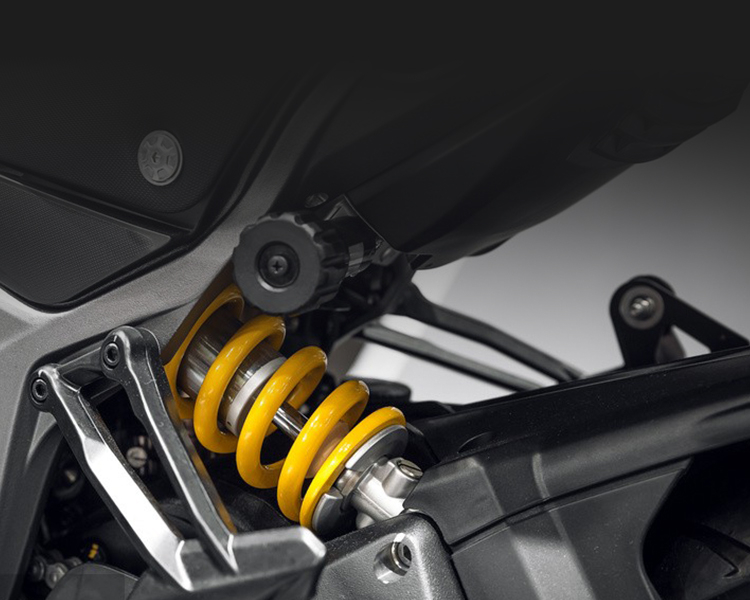

2. Electrostatic Coating

Electrophoretic coating can improve corrosion resistance and oxidation resistance.

3. Superb Stability

Each coil spring is specially designed to restore the ride height and support the weight of the vehicle, reducing body shaking and improve the handling performance.

4. High Performance

PERFECTRAIL® parts are OE manufactured to meet expectations for fit, form, and function, offering high quality and great value.

Strut Assembly

WHO WE ARE

Leading Brand in Suspension Parts.

Over 13 years' experience in manufacturing and exporting. We help the customers to grow bigger and bigger. We are not only a supplier but a business consultant.

WHAT WE OFFER

Full Line of Suspension Parts.

PERFECTRAIL® offers full line of quality suspension parts like Complete Strut Assemblies, Conversion Kits, Performance Strut Assemblies, Air Suspension and so on.

WHY CHOOSE US

Service, Quality & Growth.

From the product searching, brand design and promotion to the whole shipping, customs clearance, we provide full line solutions for you to avoid any risk.

Product Details

| Product Name | PERFECTRAIL® 2113209513 2113209613 Front Air Suspension Shock Strut For Mercedes Benz E-Class W211 4WD |

| OEM No. | FL: 2113209513 FR: 2113209613 |

| Car Model | For Mercedes Benz E-Class W211 2003-2009 For Mercedes Benz E-CLASS T-Model (S211) 2003-2009 |

| Position | Front Axle |

| Brand | PERFECTRAIL® |

| Size | As Per OEM Standard |

| Tube Material | Steel Q235B |

| Thickness of the Tube | 1.5 to 2.3mm |

| Piston Rod Material | Steel No. 35 |

| Oil Seal Material | NBR+65Mn+40Mn |

| Hardness of the Oil Seal | A75-85 |

| Damping Force Test | Both Compression and Recovery Tests |

| Stroke Test | Both Tensile and Compression Tests |

| Packing Style | Neutral, Perfectrail® or Customized Packing is acceptable |

| Warranty | 12 Months or 50,000KM (Either comes first). |

The key points of production technology of automobile air shock absorbers (Air Suspension) mainly include the following aspects:

Material selection:

- The material of the air spring must have excellent wear resistance and aging resistance, and synthetic rubber and synthetic fiber reinforced materials are commonly used.

- The outer shell of the shock absorber usually uses high-strength aluminum alloy or steel to ensure the stability and durability of the structure.

Design and manufacturing:

- The stiffness of the air spring and the shape of the airbag need to be accurately calculated during design to ensure that it can provide stable support under different load conditions.

- The airbag of the air spring must be strictly sealed to avoid air leakage.

- The internal structure design of the shock absorber needs to consider the flow characteristics of gas and oil to achieve the best shock absorption effect.

Gas control system:

- It is necessary to be equipped with a high-precision gas compressor and an electronic control system to adjust the air pressure in the airbag to ensure shock absorption effect and driving comfort.

- The control system needs to have a real-time monitoring function and can automatically adjust the air pressure according to changes in vehicle load.

Assembly and testing:

- During the assembly process, all parts must be accurately docked to avoid air leakage or poor shock absorption performance.

- During the production process, strict testing is required, including pressure testing, durability testing and performance testing, to ensure that the product meets the design specifications and usage requirements.

Maintenance and maintenance:

- During the production process, it is necessary to ensure the maintainability of the air shock absorber to facilitate subsequent maintenance and repair.

- Regularly check and replace air springs and other related parts to avoid affecting vehicle performance due to aging or damage.

These points not only affect the performance and life of the shock absorber, but also the safety and comfort of driving.

Laser Welding

Stable welding process,the surface and interior of the weld are integrated, guaranteed quality

Damping Design

Damping design shock absorption filtration, with stable and reliable quality, keep it no oil-leakage no noise and no friction

High Quality Rubber

High quality rubber,

keep it no oil-leakage no noise and no friction

Reinstall In Situe Fit Perfectly

One-stop Shopping Experience

High-quality Materials

Spraying

Test on accessories

Final assembly

Test on temperature

Test on hardness

Strut Assembly Production Line

ISO/TS16949/Patents Awarded

Our Company Has 30+ Patents Awarded

A:We have very professional engineers who can well study samples and drawings. So we surely can produce according to samples and technical drawings.

A:T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance. Ali Trade Assurance is also welcomed.

A:EXW, FOB, CFR, CIF.

A:Generally, it will take 15 to 60 days after receiving your deposit. The specific delivery time depends on the items and the quantity of your order.

A:We have whole sets of test facilities and professional test team. Every product is well tested before shipment.

A:Our quality warranty is 12 months or 50000km after delivery (Either comes first).

1. Easy to Install

Fully-assembled unit includes everything you need for strut replacement. No need for coil spring compressor and special tools.

2. Electrostatic Coating

Electrophoretic coating can improve corrosion resistance and oxidation resistance.

3. Superb Stability

Each coil spring is specially designed to restore the ride height and support the weight of the vehicle, reducing body shaking and improve the handling performance.

4. High Performance

PERFECTRAIL® parts are OE manufactured to meet expectations for fit, form, and function, offering high quality and great value.

Strut Assembly

WHO WE ARE

Leading Brand in Suspension Parts.

Over 13 years' experience in manufacturing and exporting. We help the customers to grow bigger and bigger. We are not only a supplier but a business consultant.

WHAT WE OFFER

Full Line of Suspension Parts.

PERFECTRAIL® offers full line of quality suspension parts like Complete Strut Assemblies, Conversion Kits, Performance Strut Assemblies, Air Suspension and so on.

WHY CHOOSE US

Service, Quality & Growth.

From the product searching, brand design and promotion to the whole shipping, customs clearance, we provide full line solutions for you to avoid any risk.

Product Details

| Product Name | PERFECTRAIL® 2113209513 2113209613 Front Air Suspension Shock Strut For Mercedes Benz E-Class W211 4WD |

| OEM No. | FL: 2113209513 FR: 2113209613 |

| Car Model | For Mercedes Benz E-Class W211 2003-2009 For Mercedes Benz E-CLASS T-Model (S211) 2003-2009 |

| Position | Front Axle |

| Brand | PERFECTRAIL® |

| Size | As Per OEM Standard |

| Tube Material | Steel Q235B |

| Thickness of the Tube | 1.5 to 2.3mm |

| Piston Rod Material | Steel No. 35 |

| Oil Seal Material | NBR+65Mn+40Mn |

| Hardness of the Oil Seal | A75-85 |

| Damping Force Test | Both Compression and Recovery Tests |

| Stroke Test | Both Tensile and Compression Tests |

| Packing Style | Neutral, Perfectrail® or Customized Packing is acceptable |

| Warranty | 12 Months or 50,000KM (Either comes first). |

The key points of production technology of automobile air shock absorbers (Air Suspension) mainly include the following aspects:

Material selection:

- The material of the air spring must have excellent wear resistance and aging resistance, and synthetic rubber and synthetic fiber reinforced materials are commonly used.

- The outer shell of the shock absorber usually uses high-strength aluminum alloy or steel to ensure the stability and durability of the structure.

Design and manufacturing:

- The stiffness of the air spring and the shape of the airbag need to be accurately calculated during design to ensure that it can provide stable support under different load conditions.

- The airbag of the air spring must be strictly sealed to avoid air leakage.

- The internal structure design of the shock absorber needs to consider the flow characteristics of gas and oil to achieve the best shock absorption effect.

Gas control system:

- It is necessary to be equipped with a high-precision gas compressor and an electronic control system to adjust the air pressure in the airbag to ensure shock absorption effect and driving comfort.

- The control system needs to have a real-time monitoring function and can automatically adjust the air pressure according to changes in vehicle load.

Assembly and testing:

- During the assembly process, all parts must be accurately docked to avoid air leakage or poor shock absorption performance.

- During the production process, strict testing is required, including pressure testing, durability testing and performance testing, to ensure that the product meets the design specifications and usage requirements.

Maintenance and maintenance:

- During the production process, it is necessary to ensure the maintainability of the air shock absorber to facilitate subsequent maintenance and repair.

- Regularly check and replace air springs and other related parts to avoid affecting vehicle performance due to aging or damage.

These points not only affect the performance and life of the shock absorber, but also the safety and comfort of driving.

Laser Welding

Stable welding process,the surface and interior of the weld are integrated, guaranteed quality

Damping Design

Damping design shock absorption filtration, with stable and reliable quality, keep it no oil-leakage no noise and no friction

High Quality Rubber

High quality rubber,

keep it no oil-leakage no noise and no friction

Reinstall In Situe Fit Perfectly

One-stop Shopping Experience

High-quality Materials

Spraying

Test on accessories

Final assembly

Test on temperature

Test on hardness

Strut Assembly Production Line

ISO/TS16949/Patents Awarded

Our Company Has 30+ Patents Awarded

A:We have very professional engineers who can well study samples and drawings. So we surely can produce according to samples and technical drawings.

A:T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance. Ali Trade Assurance is also welcomed.

A:EXW, FOB, CFR, CIF.

A:Generally, it will take 15 to 60 days after receiving your deposit. The specific delivery time depends on the items and the quantity of your order.

A:We have whole sets of test facilities and professional test team. Every product is well tested before shipment.

A:Our quality warranty is 12 months or 50000km after delivery (Either comes first).

+86-25-57596088

+86-18952079998

+86-18952079998

No.150 Pubin Rd., Jiangbei New District, Nanjing City, Jiangsu Province, China CHN211800