Views: 0 Author: Site Editor Publish Time: 2023-06-30 Origin: Site

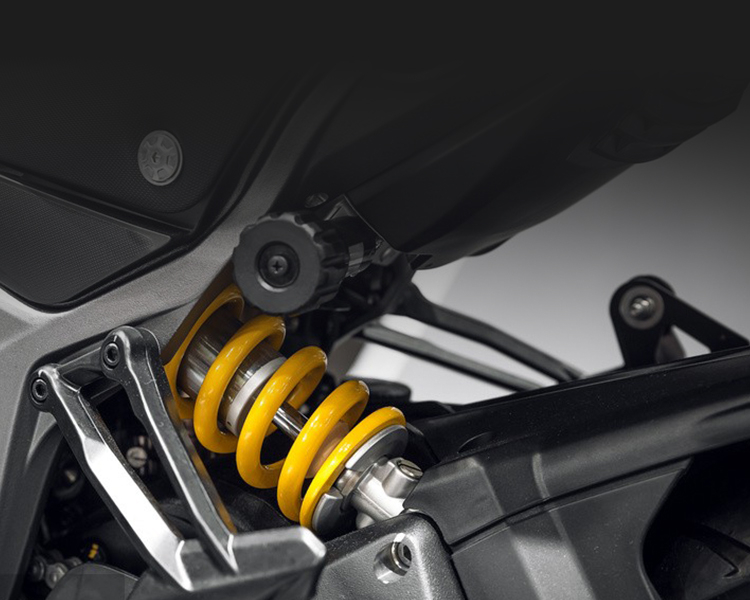

nitrogen shock absorbers are a type of shock absorbers that use pressurized nitrogen gas to provide damping and stability for vehicles. They are widely used in various applications such as cars, motorcycles, aircrafts, and industrial machines. nitrogen shock absorbers have several advantages over conventional oilfilled shock absorbers, such as better performance, durability, and resistance to heat and corrosion.

What is the history of nitrogen shock absorber?

What is the development ofnitrogen shock absorber technology?

What are the market trends for nitrogen shock absorber?

The history of nitrogen shock-absorbers can be traced back to the invention of shock absorbers in general. shock absorbers are devices that absorb and dissipate the kinetic energy of shocks and vibrations caused by uneven road surfaces or other impacts. The first shock absorbers were mechanical springs that were attached to the wheels or axles of vehicles. However, these springs were not very effective and could cause bouncing and instability.

The next development was hydraulic shock absorbers, which used oil or water as a damping medium. These shock absorbers were invented by Maurice Houdaille in 1908 and were first used by Renault in 1926. Hydraulic shock absorbers consisted of a cylinder filled with oil or water and a piston that moved inside the cylinder. The movement of the piston created pressure and friction that reduced the shocks and vibrations.

Monotube shock absorbers: These are shock absorbers that have only one tube instead of two tubes (inner and outer) as in conventional twintube shock absorbers. Monotube shock absorbers have larger pistons and valves that allow more oil flow and faster heat dissipation. They also have less moving parts and less friction than twintube shock absorbers.

Reservoir shock absorbers: These are shock absorbers that have an external reservoir that stores extra oil or gas for increased damping capacity. Reservoir shock absorbers can handle higher loads and temperatures than standard shock-absorbers. They also allow more adjustment and tuning options for different driving conditions.

Electronic shock absorbers: These are shock-absorbers that have electronic sensors and actuators that control the damping force according to the road conditions and driver preferences. Electronic shock absorbers can adapt to different terrains and speeds automatically or manually. They can also communicate with other vehicle systems such as steering, braking, and stability control.

nitrogen shock absorber technology has evolved over time to meet the changing needs and demands of drivers and vehicles. There are different types of nitrogen shock absorbers, such as twin-tube shocks, monotube shocks, reservoir shocks, etc. Each type has its own advantages and disadvantages, depending on the design, construction, and application.

Twin-tube shocks are the most common type of nitrogen shock absorbers. They consist of two tubes: an inner tube that houses the piston shaft assembly, base valve, and oil; and an outer tube that contains both nitrogen gas and hydraulic oil. The advantage of twin-tube shocks is that they have a short installation length and are more durable against road debris. The disadvantage is that they have a small diameter of the working piston and a small effective surface area, which results in high pressures and increased wear.

If you are looking for a supplier of high quality nitrogen shock absorber for home at a reasonable price , Ido Group Co., Ltd. is a very good choice.

+86-25-57596088

+86-18952079998

+86-18952079998

No.150 Pubin Rd., Jiangbei New District, Nanjing City, Jiangsu Province, China CHN211800